|

Veneer Figures |

|

|

|

|

|

|

|

Bird's Eye - Characterized

by its scattered circles or ovals that have a similar appearance

to that of a bird's eye. This type of figure is found almost

exclusively in Hard Maple. |

|

|

|

|

|

|

|

Burl (or Burr) Veneer - Veneer

obtained from rare woody outgrowths appearing on trees around

grafts or injuries. This produces an appearance of a close

arrangement of many small eyes or knots intermingled with

distorted grain. The unusual patterns of burls make them

in high demand but also more expensive due to their small

size and scarcity. |

|

|

|

|

|

|

|

Crossfire - This term is used

to describe all of the various figure marks running perpendicular

to the veneer grain. In some wood species the crossfire

is a contrast of color, while others appear as an irregularity

of the grain creating the illusion of horizontal marks. |

|

|

|

|

|

|

|

Crotchwood - This type of

figure occurs where limbs emerge from the tree trunk. The

high amounts of fiber distortion at this junction results

in a feather or flame pattern appearance. Mahogany is the

most common specie with this type of figuring. |

|

|

|

|

|

|

|

Curly - The term used for

a wavy or curly figuring produced by distorted fiber growth

that reflects light differently. Most commonly available

in Walnut and Maple veneers. |

|

|

|

|

|

|

|

Fiddleback - A term describing

consistent ripple figure running across the grain. Fiddleback

is not commonly found but occasionally occurs in Mahogany,

English Sycamore, and Anigre. The term fiddleback comes

from the veneer's popularity in making violin backs. |

|

|

|

|

|

|

|

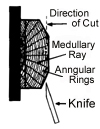

Flake - This is found only

in species that have prominent medullary rays (cells radiating

outward from the center of the tree, like the spokes of

a wheel.) By slicing the veneer perpendicular to the annular

rings and parallel with the rays, a distinctive "flake"

within the figure is created. |

|

|

|

|

|

|

|

Mottle - Mottle is the intermingling

of broken cross markings with stripe figure. Block mottle

involves broad cross markings producing a patch effect and

is commonly found in Makore. Bees-wing-mottle is very small,

fine figure and often occurs in Sapele, Satinwood and Black

Bean. |

|

|

|

|

|

|

|

Plain Stripe and Ribbon Stripe

- The figure is straight and parallel with the length of

veneer as a result of quarter slicing the log. Ribbon stripe

is similar but with variable width bands, alternating light

and dark, that create the appearance of ribbons. |

|

|

|

|

|

|

|

Peanut Shell - A quilted or

blistered figure that incorporates a dominant grain or yearring

pattern. Mostly found in Tamo or Bubinga. |

|

|

|

|

|

|

|

Pommele - Pommele gets its

name from the French word for "apple." The figure

resembles small round or oval circles that can overlap each

other. Sometimes a log that has larger and more sparsely

occurring "apples" can be referred to as blistered.

|

|

|

|

|

|

|

|

Quilted - This figuring is

produced by rotary or half-round slicing of logs that have

a "bumpy" surface. The uneven weaving of the growth

rings produces a quilted, three-dimensional effect. Maple

and Mahogany are species often available with quilted figure.

|

|

|

|

|

|

|

|

Recomposed or Man-made Veneers

- These veneers are sliced from man-made "cants"

that have been laminated, or resliced, to produce distinctive

figures or patterns. |

|

|

|

|

|

|

|

|

Veneer Cuts |

|

|

|

|

|

|

|

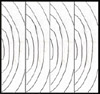

Flat Cut or Plain Sliced -

(defined by a cathedral or heart) Half a log is mounted

on a large steel rack which moves up and down through a

stationary knife through a series of vertical, parallel

cuts. This produces consecutive leaves of veneer with the

standard appearance of veneer (the "cathedral"

or flame-shaped arch). When a log is flat cut it will generate

flat cut bundles. As you get to the center of the log, normally

the rest of the flitch is split open to produce a quartered

look called flat cut quarters.

|

|

|

|

|

|

|

|

Half Round Slicing - (modified

characteristics of both rotary and flat cut veneers) A half

of a log is mounted so that it will cause the blade to cut

slightly across the growth rings. This is primarily used

to accentuate the grain in various woods such as in burls

or Bird's Eye Maple, or to gain a wider width on a cathedral

on small dimension logs. |

|

|

|

|

|

|

|

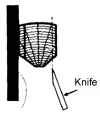

Quarter Cut - (straight grain

or ribbon-striped appearance) A quarter of the log is mounted

off center so that the growth rings strike the knife at

a right angle. The edge of the annual rings create the lineal

figure of the veneer. Quartered leaves cut consecutively

are narrower than plain sliced and typically contain straighter

grain. Some flake is produced when cutting through the medullary

rays, especially in Oak. |

|

|

|

|

|

|

|

Rift Cut - (a straight grain

effect similar to true quarter cut veneer) Used in Oak to

minimize the "flake" effect, the cant is cut at

an angle of 15 degrees off the quartered position. |

|

|

|

|

|

|

|

Rotary Cut - (creates a bold

sometimes wild, variated grain) An entire log is mounted

so that the log turns on its long axis. While spinning,

the knife advances toward the center of the log slicing

or peeling a continuous sheet of veneer. Sometimes a score

line is cut into the log to give the effect of consecutive

sheets. This is especially true of burls and Bird's Eye

Maple. |

|

|

|

|

|

|

|

|

Veneer Matches |

|

|

|

|

|

|

|

Balance Match - The width

of each veneer leaf in a panel is the same, but there can

be any number of leaves. |

|

|

|

|

|

|

|

Book Match - Every other leaf

is turned over like the pages in a book. This is the most

popular matching method and creates a symmetrical pattern

and a series of pairs. |

|

|

|

|

|

|

|

Butt or End Match - The veneer

is joined end to end and side to side. This is sometimes

used when the veneer is not long enough to cover the desired

panel height. It is also a popular method for burls, crotches,

and highly decorative veneers. |

|

|

|

|

|

|

|

Book and Butt Match - The

veneer is joined from side to side and end to end. |

|

|

|

|

|

|

|

Center Match - Each face has

an even number of veneer sheets, but the widths are not

necessarily the same. The center joint will be in the middle

of the panel. |

|

|

|

|

|

|

|

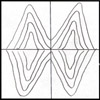

Diamond Match/Box Match -

Four equal pieces of veneer are cut diagonally to the usually

straight grain. These are matched to create a diamond pattern.

In a reverse diamond match, the pieces are matched so that

the grain direction runs toward the middle. |

|

|

|

|

|

|

|

Pie Match/Sunburst Match -

Consecutive sheets are trimmed into pie shaped pieces and

matched in a circular fashion in which the points meet in

the center. Mostly used on round, oval or octagonal shaped

panels. |

|

|

|

|

|

|

|

Random Match - Deliberate

mismatched leaves are placed next to each other to give

a rustic, natural look. This works especially well with

knotty or wormy species. |

|

|

|

|

|

|

|

Slip Match - Consecutive sheets

are slipped out in sequence to expose the same side of veneer

and a repeating grain figure. The result is a series of

grain repeats, but no pairs. |

|

|

|

|

|

|

|

|

Other Veneer Terms |

|

|

|

|

|

Backed

Veneer |

|

Veneer which has been backed with

special paper laminate veneer or other material. |

|

|

|

|

|

Butt

End |

|

Part of the veneer corresponding

to the stump-wood from which it was obtained. |

|

|

|

|

|

Checks |

|

Splits in the longitudinal separation

of the fibers in the veneer or that may occur at the joining

of the veneer leaves. |

|

|

|

|

|

Clipper |

|

A machine that uses a swinging knife

for trimming and clipping. |

|

|

|

|

|

Clipping |

|

The process for trimming veneer to

make it suitable for jointing or to cut out undesirable

patterns or defects. |

|

|

|

|

|

Dye |

|

Vat or pressure infused process to

produce colored veneers. |

|

|

|

|

|

Edge

Banding |

|

Strips of veneer joined continuously

head-on to be applied onto the sides of the substrate. |

|

|

|

|

|

Finger

Jointing |

|

Joining together two veneers by means

of a series of interlocking "fingers" at the edge

ends and held together with an adhesive. |

|

|

|

|

|

Flattened

Veneer |

|

Veneer which has undergone flattening

operations. |

|

|

|

|

|

Gum |

|

A small patch of accumulated gum

(mineral or resin) that commonly occurs in American Cherry

and Beech. It is often the result of crown damage, bird

pecks, or other insect damage. |

|

|

|

|

|

Hand

Sample |

|

Approximately 8"x11", a

hand sample may be from a specific log or may be a general

type sample representing a species as a whole. |

|

|

|

|

|

Heartwood |

|

The inner core of a mature log, usually

darker in color that the sapwood. |

|

|

|

|

|

Holes |

|

Holes in the veneer due to the loss

of loose knots or caused by defects in the log. |

|

|

|

|

|

Inlay |

|

Thin strips of veneers used for decorative

purposes. Usually sold in one meter lengths, the various

types commercially available today are; Stringings, Flat

lines, Square lines, Purfling and Bandings. |

|

|

|

|

|

Knot |

|

A place in the wood where a branch

had grown out of the heartwood. |

|

|

|

|

|

Live

Sample |

|

Single sheets of veneer pulled out

of a log to represent the whole log. (Our live samples are

sent for selection, and those not chosen must be returned

or a resampling charge will be accessed.) |

|

|

|

|

|

Marquetry |

|

Joining veneers of different colors

and species to obtain a specific pattern. |

|

|

|

|

|

Matching |

|

Joining veneers in a sequence according

to their natural sequential order or to obtain specific

dimensions and a pattern desired. |

|

|

|

|

|

Numbering |

|

Assigned for inventory and sampling

purposes. Log number: each log is assigned a separate number.

Flitch number: half a log is given a separate number. Section

number: sometimes different sections are numbered by adding

a dash and another number to the log or flitch number to

show it came from the same tree. Bundle number: number given

to a specific number of sheets that are tied together. |

|

|

|

|

|

Pallet |

|

Pallet - A flat wooden frame used

to handle and store or ship bundles of veneer.

|

|

|

|

|

|

Pinknot |

|

A single cluster of very small knots. |

|

|

|

|

|

Pore |

|

A minute opening that is a moisture

conducting cell. |

|

|

|

|

|

Pre-Dyed

Veneer |

|

Veneer that has been dyed throughout

with any color before it is applied to a substrate. |

|

|

|

|

|

Resin |

|

Natural vegetable substance found

in the wood of many trees, especially conifers. Similar

to pitch pocket. |

|

|

|

|

|

Sap |

|

A juice or circulating fluid found

in trees. |

|

|

|

|

|

Sapwood |

|

The soft wood beneath the inner bark

through which the sap flows. Often lighter in color than

the central heartwood. |

|

|

|

|

|

Solid

Wood |

|

Wood thicker than three millimeters

(approximately an eighth of an inch). |

|

|

|

|

|

Splits |

|

Cracks or tears in the veneer. |

|

|

|

|

|

Stained

Veneer |

|

A veneer which has been stained by

an external factor such as mold, light, grease etc., or

end stain which is the stain that often occurs at the end

of a log. |

|

|

|

|

|

Steamed

Veneer |

|

Veneer obtained from logs that have

been pre-treated by steaming. |

|

|

|

|

|

Stump-Wood

Veneer |

|

Veneer obtained from the butt log

or "stump" of a tree. Marked with irregular veining.

|

|

|

|

|

|

Trimmed

Veneer |

|

Veneer which has undergone trimming.

|

|

|

|

|

|

Trimming |

|

Veneer is trimmed lengthwise to remove

defects and to make the veneer sides parallel and suitable

for joining. |

|

|

|

|

|

Visible

Surface Veneer |

|

The veneer that is to be applied

to the visible side of the substrate. |

|

|

|

|

|

Waste |

|

The part of the veneer that is removed

during trimming. |

|

|

|

|

|

Yield |

|

The calculation of raw veneer footage,

necessary to make net footage on panels. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|